Unleash the Power of Photo-Chemistry

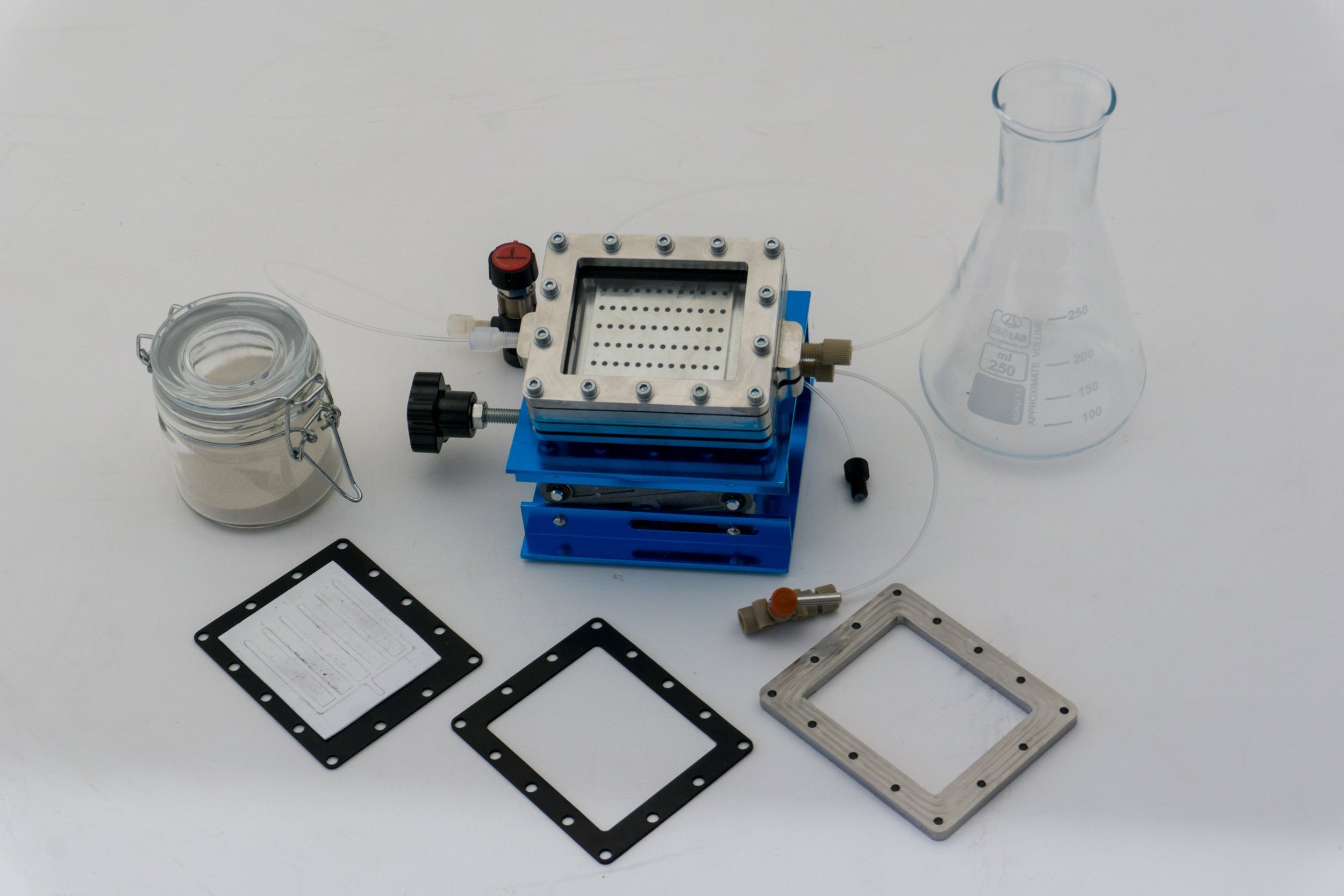

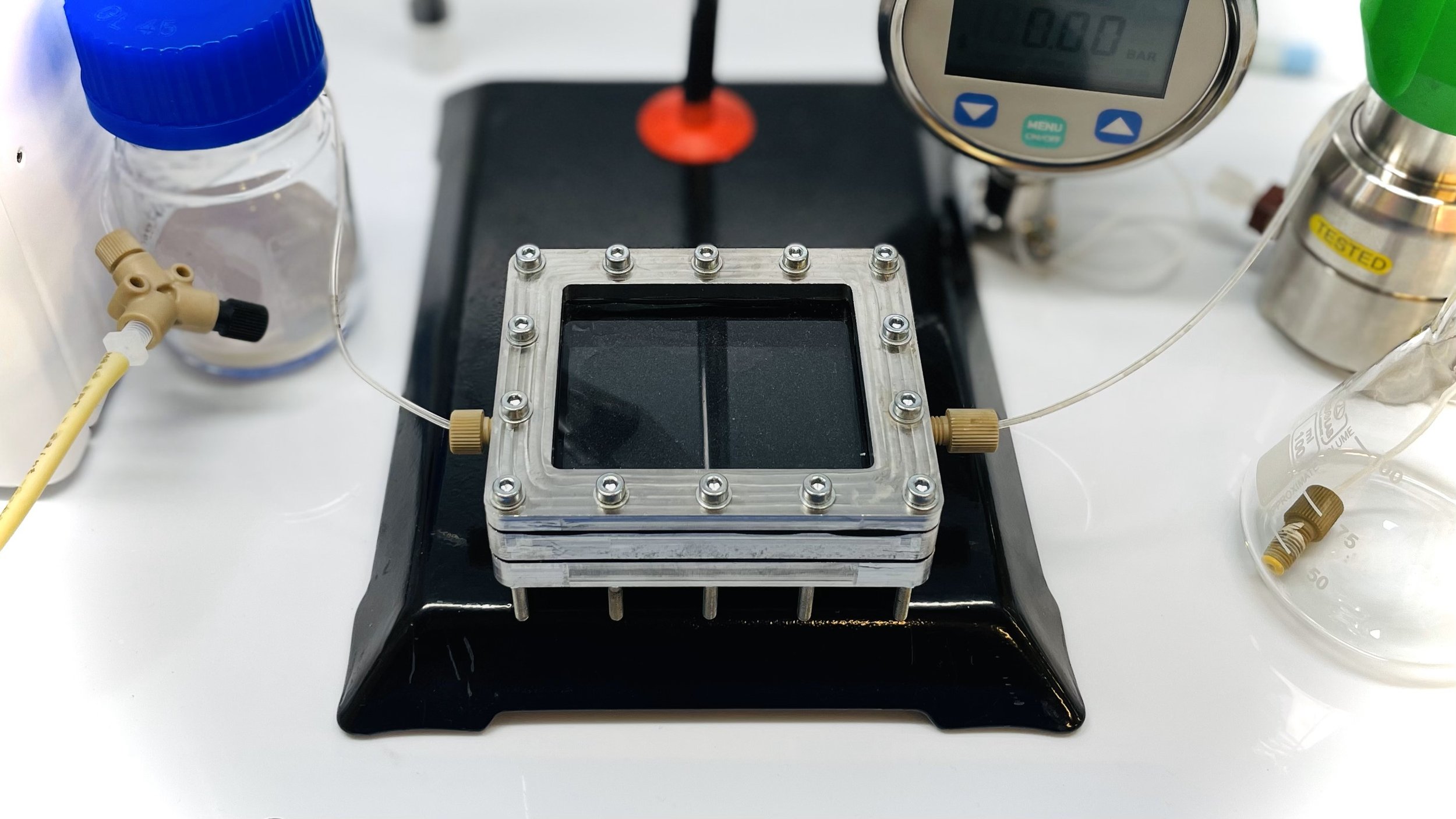

with Redeem’s Continuous-Flow Photo-Reactor

Already discovering new chemistry at:

Features

The Redeem Photo-Flow reactor combines the benefits of photochemistry and continuous-flow processes for the highest possible versatility at a competitive price. We guarantee a perfect fit by the maximization of catalyst activity and light utilization by customizing the channel depth and the optional integrated membrane. The option to trap a solid catalyst inside avoids tedious catalyst separation and together with the easy cleaning and maintenance this reduces workload and cost to a minimum. No other photo-flow reactor on the market offers such a wide range of applications and makes transitioning from batch to flow easier.

Flow Photo-Reactor

-

Combines the benefits of flow chemistry (Easy quality control, high reproducibility, intensified process and safe operation) and photo-catalysis (Atom efficiency, low temperature, renewable energy and high selectivity) to maximize your efficiency.

-

Choose the ideal channel depth and materials tailored to your specific chemical requirements. An integrated membrane or individual mixing patterns can be added if needed.

-

Scalabale photochemistry made easy with different reactor sizes for mg/h to t/y production.

-

Highly pure product as no catalyst removal step is needed. Ensures more than 8 times longer catalyst lifetime.

Technical Specifications (Mini-Redeem basic model)

A Wide Range of Applications

From laboratory R&D and process development to pilot plant design and large-scale industrial production, our continuous-flow reactor is designed for seamless integration. Prioritizing user experience, safety, sustainability and optimal process control, our system ensures easy handling and maintenance. Effortlessly transition from batch to continuous-flow with our user-friendly design.

Reductive Decarboxylation

α-Amino Oxidation

Dehydrogenation

C-H Trifluoromethylation

C-C Cross Coupling

Ammonia Synthesis

CO2 Reduction

Pollutant Degradation

and many more…