PRODUCTS

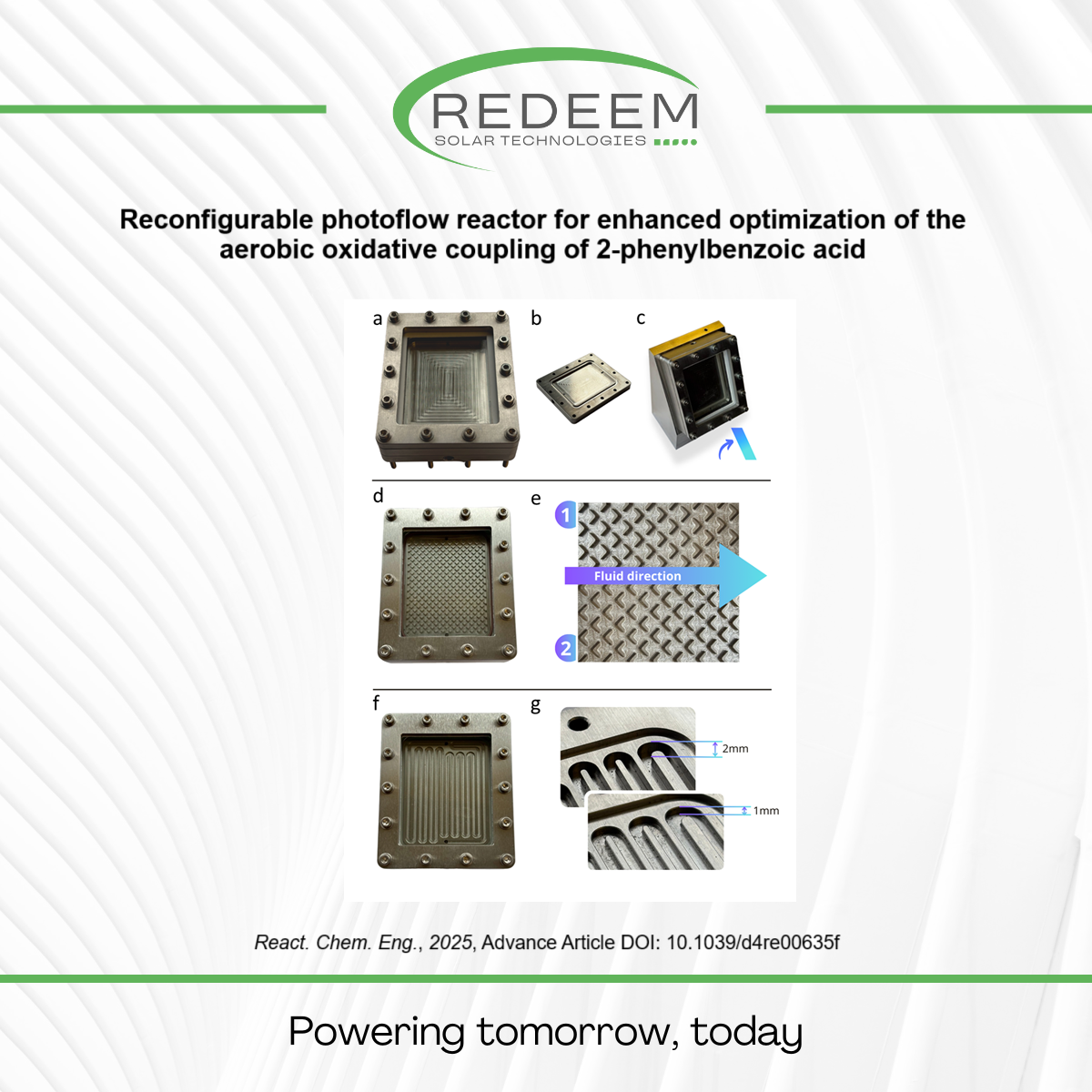

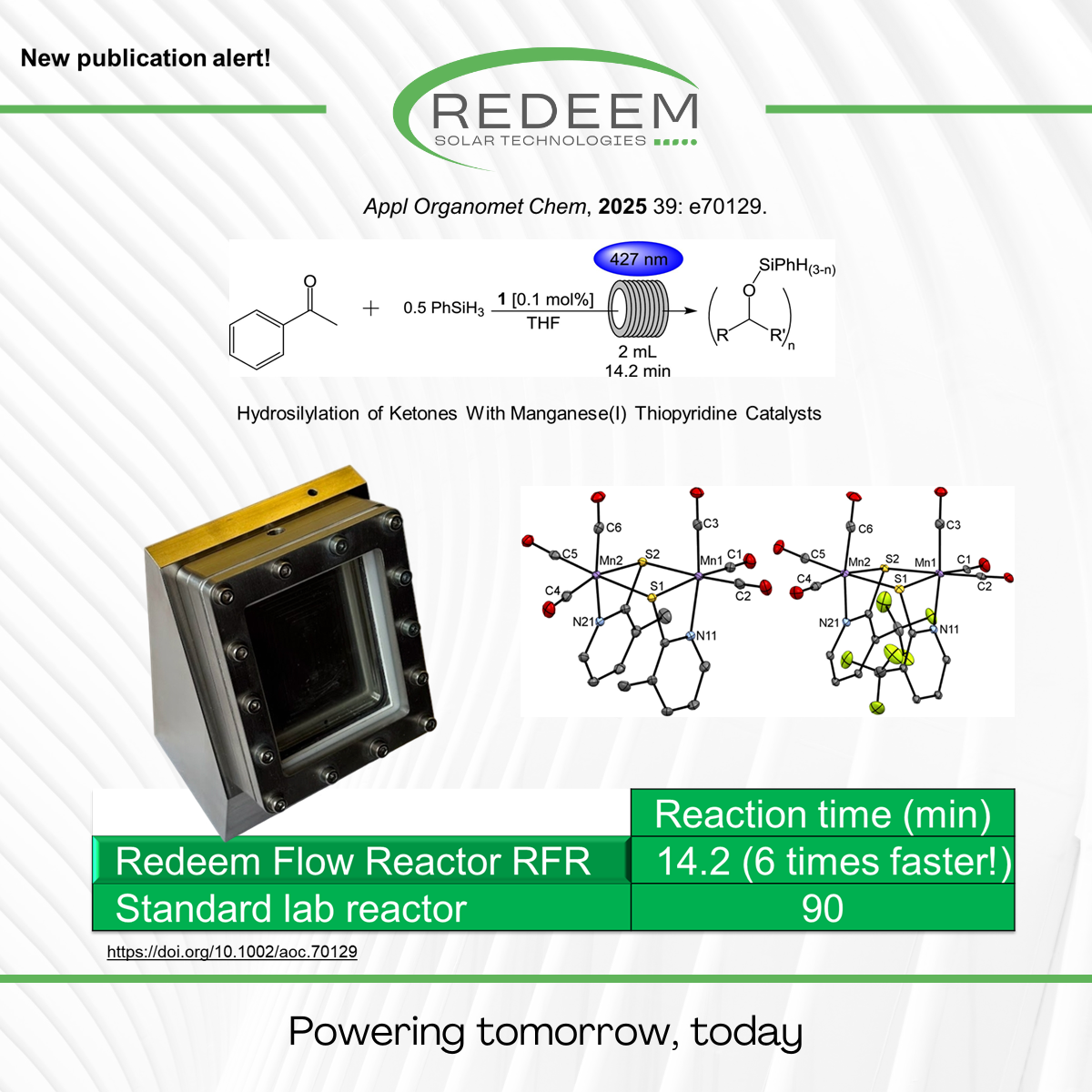

Redeem Flow Reactors (RFR)

The most versatile flow rectors with more than 10 different models, explore how the Redeem Flow Reactors can boost your chemistry!

Applications

POWERFUL APPLICATIONS

Experience the Future of Green Chemistry: The Redeem Flow Reactor in Action!

For The Speciality Chemicals Industry

Redeem's flow reactors revolutionize chemical manufacturing by harnessing the benefits of continuous manufacturing to the max and optionally combine them with photo-catalysis for atom-efficient processes... and more!

For The Pharmaceutical Industry

Experience rapid screening of diverse processes with Redeem's flow-reactors and catalyst screening kits, ensuring swift development timelines and fast time to market with your new sustainable building blocks... and more!

For Research and Development

Experience rapid screening of diverse reactor models with Redeem's flow-reactors. Whether its industry or academic R&D, we offer the widest variety of flow reactors with the ability for customization…and more!

WHY THE REDEEM FLOW REACTOR?

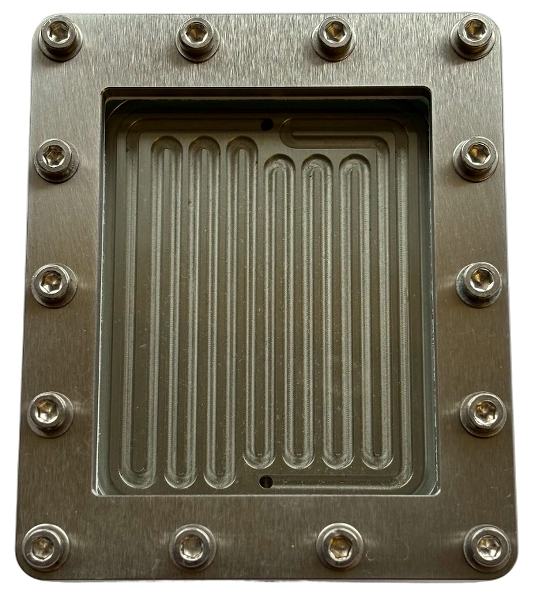

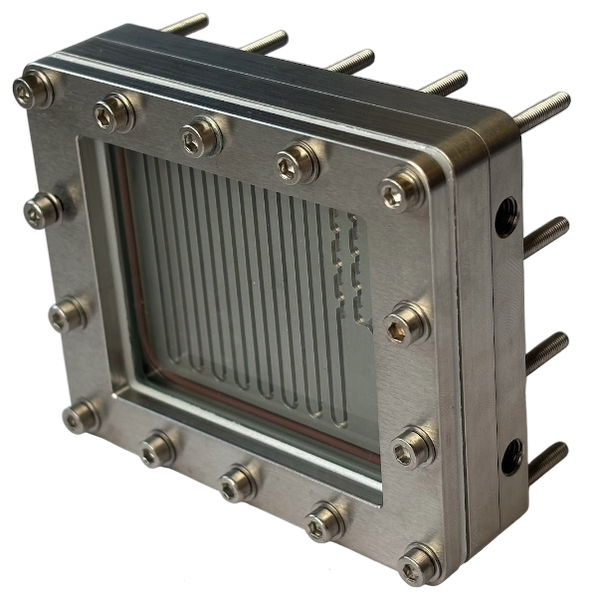

The Advantages of the Redeem Flow Reactor (RFR)

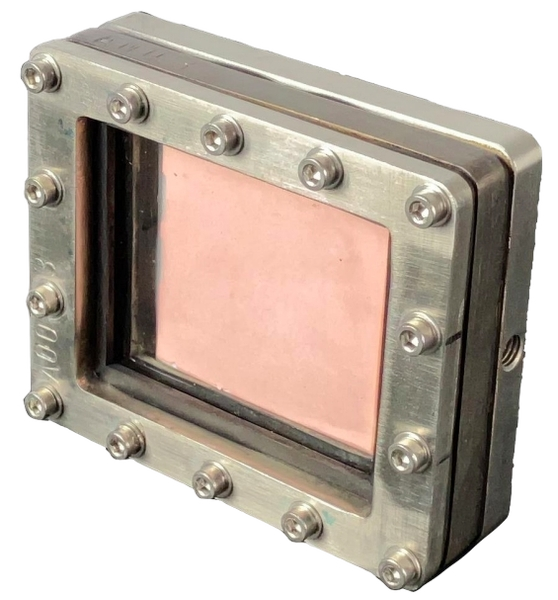

Product Quality

High and steady quality as the continuous production process reduces the variability between batches. Minimum off-spec waste with the transparent window for reaction monitoring in the Redeem Flowreactor.

Sustainable

Our technology ensures sustainability over the entire life cycle. We built our technology with the environment in mind; our reactors are well suited for photochemical and solar chemical transformations with renewable energy to give our customers the best ESG metrics.

Cost-Efficient

Lower your operating costs by maximizing atom and energy efficiency in your chemical transformation with Redeem's wide selection of flow reactor configurations. By asking for a Redeem Flow Reactor with integrated separation, you can reduce the equipment count.

Speed to Market

We offer reactors from lab scale, through pilot plants, and all the way to commercial production plants. The Redeem Flow Reactor system features a modular design that enables seamless assembly and disassembly of individual components or units. This design not only facilitates efficient maintenance but also allows for easy upgrades and expansions without disruption to the overall system's operation.

Durable

Our reactors are made to endure harsh chemical conditions. We can configure our reactors to withstand high pressure and temperatures exceeding normal operation conditions. Producing corrosive chemicals is no problem for our flow reactors.

Enable Multi-Phase Reactions

RFRs are designed to fit in multiple applications, including multi-phase reactions, slurry processing, and equilibrium-limited reactions. Their flexibility stems from the configurable design, which allows for tuning the flow properties and optionally integrating a membrane for phase separation within the RFR itself.